The rush for silver helped establish Nevada as the 36th state in 1864, and a wealth of resources has continued to fuel mining in the state. The industry supports around 15,000 direct jobs, along with another 28,000 adjacent positions. But working in mines involves inherent risks from the air pollution created by coring into the Earth. To help protect miners and assist mine managers in reducing hazardous exposures, DRI scientists Xiaoliang Wang, Judy Chow, and John Watson are conducting free trainings to raise awareness about health risks and effective protection methods.

“A lot of people don’t think much about indoor air pollution, which can occur at work and at home,” says Xiaoliang Wang, Research Professor of Atmospheric Science and project lead. “By leveraging our expertise in air quality, we can help protect Nevada miners from hazardous pollutants while also assisting mines in meeting regulatory requirements.”

Mines in Nevada produce a range of metals and other goods, including gold, silver, copper, gypsum, limestone, clay, lithium, and the ingredients needed to produce cement. These essential resources support modern infrastructure, including batteries, electronics, wiring, and housing. But the process to extract them from Earth’s soil and rocks releases large amounts of dust to the air. A primary component of rocks is silica, and its crystalline form poses one of the greatest risks to miner health. When silica dust makes its way into a person’s lungs, it scars the delicate cells responsible for absorbing oxygen. Larger dust particles can lodge in the mouth and nose, while the smallest particles reach deep into the lungs. Repeated and prolonged exposure to silica dust can cause silicosis, emphysema, chronic bronchitis, lung cancer, kidney disease, and autoimmune disorders. Data from the Mine Safety and Health Administration (MSHA) show that as much as 27% of miners are overexposed to air contaminants. The key to reducing these health risks is raising awareness, taking precautionary measures, and reducing dust emissions, the scientists say.

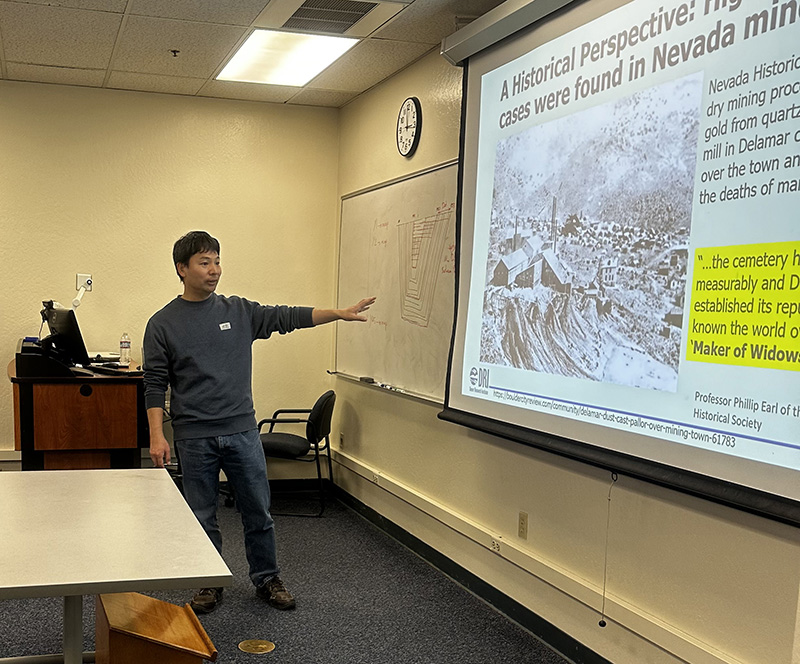

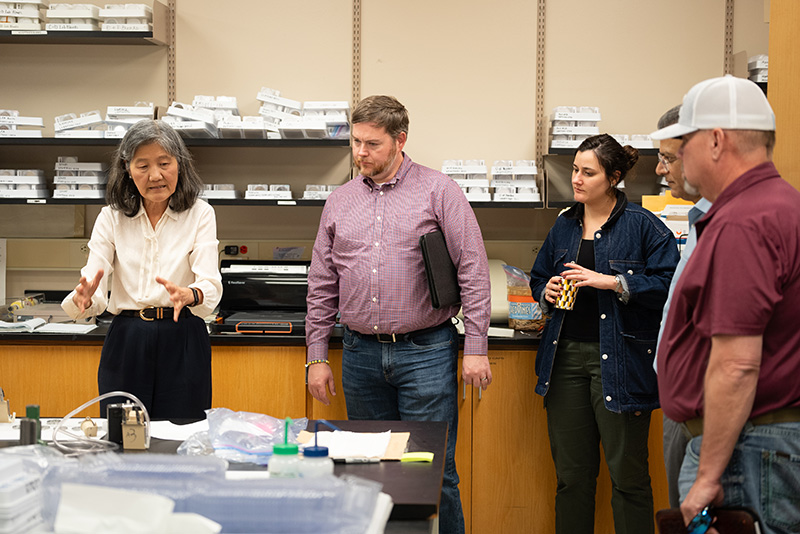

Wang and the research team have developed a comprehensive guide and training covering the health effects of hazardous dust exposure, strategies for reducing dust emissions, dust exposure limits and health statistics, and dust sampling methods. All training materials are available to the public in both English and Spanish on DRI’s website. The materials were presented to nearly 500 miners, mine managers, and safety trainers across Nevada throughout 2024, with a focus on silica dust because of a newly published MSHA silica rule reducing the exposure limit. By sharing the information with those who will continue to provide new miner and annual refresher trainings across the state, the project will extend its impact well beyond the initial trainees.

“There are a lot of questions about the new silica rule, and our training can help the mine companies and also the miners to understand what the new rule entails, what the requirements are, and what they can do to reduce silica dust emissions in the mine,” Wang says.

Additional trainings focused on respirator protection will occur April-September 2025 in Reno, Las Vegas, and Winnemucca. With a wide variety of respirators available, Wang says the training will help miners understand how to choose the right one for their needs, as well as when and how to wear it properly.

“We are all familiar with N95 masks, but in the mining environments, a much wider range of respirators is used,” Wang says. “Many people don’t like to wear respirators due to discomfort, but in mining, not wearing one can have serious health consequences. The diseases that develop are not reversible.”

“At one training, a miner shared that at retirement parties for miners, many attendees carry oxygen tanks,” Wang continues. “These diseases take years to develop — when you work in a dusty environment, you don’t get sick right away. As a result, many workers don’t wear masks. But once it’s too late, it’s too late.”

Exposure to mine dust, especially crystalline silica, is a major hazard to those working in both metal and nonmetal mines. Because symptoms of silicosis like shortness of breath and chronic cough can take years to develop, miners may not even notice them until after they’ve stopped working, when it’s too late to take protective measures. The symptoms can continue to worsen even long after the exposure. Lung damage caused by silicosis can also increase risks of other conditions like heart failure, tuberculosis, and chronic obstructive pulmonary disease (COPD).

The trainings are tailored for miners and mine operators. Miner training focuses on recognizing the health risks of silica and taking proper precautions, including the use of respirators. Mine operator training covers the new silica rule, dust monitoring and control technologies, and the implementation of an effective respiratory protection program.

The training programs are just one part of Wang’s work on mine air quality, which began when he joined DRI in 2009. Currently, he is also working to improve the method for measuring silica dust in a project funded by the National Institute for Occupational Safety and Health (NIOSH). The traditional method takes weeks to get results, and by then, mining conditions have changed, making it too late to reduce dust exposure. Wang’s team is refining a new, faster method that will be more practical for use in the field.

In a separate project, Wang and his colleagues are exploring methods to detect lithium-ion battery fires before they start and to suppress them effectively. The research could help mines transitioning from diesel equipment with lithium-ion battery-powered machinery, but the technology could be applied to any lithium-ion batteries.

“Many mines use diesel equipment, and diesel exhaust is known to cause cancer,”

Wang says. “Diesel machinery is hot and noisy, increasing miners’ stress, especially in underground environments.”

Equipment powered by lithium-ion batteries is quieter, cooler, and doesn’t emit pollutants, making it well-suited for use in a mine setting. But these batteries store a large amount of energy in a compact space, and under certain conditions, can rapidly catch fire or even explode. Because of the rapid pace of these fires, which can reach the temperature of a blowtorch in about a second, there are few warning signals to alert people of impending danger. When used underground, lithium-ion battery fires can be particularly hazardous and cause extensive economic loss. Wang’s project aims to identify early warning signs in batteries prone to failure, as well as effective ways to put out fires once they start.

“I hope to build trust and collaborate with the mining industry,” Wang says, “to create a heathy and safe work environment and protect the workers who produce the resources we all depend on.”

—————————————-

More information:

Miner Dust/Silica Training Program

The 2024 and 2025 trainings are funded by the Mine Safety and Health Administration’s Brookwood-Sago Mine Safety Grants

Related DRI Research:

Evaluation of PVC and PTFE filters for direct-on-filter crystalline silica quantification by FTIR

Functionalization of Filter Media for Improved Crystalline Silica Analysis Using Raman Spectroscopy

Coal Mine Dust Size Distributions, Chemical Compositions, and Source Apportionment